Smart technology

The innovative aspect of the concept is the unique combination of state-of-the-art mechanical, thermal and chemical processes, that are proven to work on industrial scale.

Plastics Recycling

A fully automated sorting line separates the mixed waste streams into different material fractions (plastics, organics, metals, …). The plastics are further separated into different categories. The hard plastics, such as HDPE and PP, can be mechanically recycled for some applications where food-contact is not a requirement. Unfortunately, there is no such market for the end-of-life plastic films. These ‘non-recyclable’ plastics often consist of multi-layer materials and are typically very dirty due to their large surface area.

Together with our off-take partner, Renasci is bridging this gap in the circularity of plastics by utilizing the plastics-to-chemicals process (P2C). This thermal process breaks down the plastic polymer into an oil which is used as feedstock for the production of virgin plastics. The main byproduct of this process is used as fuel to generate electricity for the facility. The current installation has been operational since September 2020 and on a growth path to process 20kt/a of plastic waste to chemicals.

Because of the integration into Renasci’s Smart Chain Processing concept, the P2C installation is commercially viable at this scale. The sustainability of the operation is certified by the ISCC PLUS certification system for sustainable feedstocks and materials.

Flagship Plant

The Renasci’s Smart Chain Processing facility is located in Ostend Belgium. This flagship plant combines existing technologies in an innovative configuration that can process both RDF and mixed industrial plastic waste. Construction started in Q1 2019 and the plant is fully operational since end Q1 2021. In the next phase, we intend to expand the Smart Chain Processing (SCP) concept to additional locations by working together with local partners. The flexibility of SCP allows it to be configured to answer the local waste challenge, whether this is household waste, certain types of medical waste, textile, rubber tires, sludge etc…

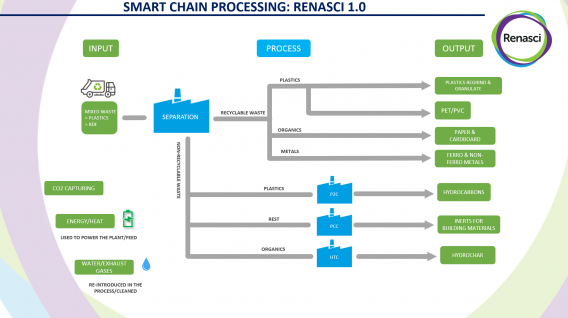

Input

The primary waste stream consists of RDF (Refuse derived fuel). Currently most RDF is being burned or dumped in landfills. In Ostend the goal is to convert yearly 102.000 tonnes of RDF and 18.000 tonnes of mixed plastics into reusable products.

Sorting

The high-end sorting installation separates the recyclable and the non-recyclable waste stream. Each flow is sorted based on its own characteristics such as magnetism, mass, density etc. The recyclable waste stream is cleaned, upgraded and presented back on the market. The non-recyclable waste stream is converted into valuable end-products.

Ferro / non-ferro

The ferrous and non-ferrous metals are removed in the process and sold as valuable raw materials.

Plastics

The sorting installation separates the recyclable and the non-recyclable plastics. The non-recyclable plastics are chemically upgraded to hydrocarbons using the P2C technology. The recyclable plastics are upgraded and sold on the market.

Organic materials

The good quality paper and cardboard are presented back on the market. The non-recyclable organic fraction is processed in the hydrothermal conversion (HTC) into hydro char pellets. The hydrothermal carbonization is recognized to be a treatment able to transform waste into a product.

The high calorific value makes it suitable to be used as a fuel substituting fossil fuels. Despite the input materials, the quality of the produced hydro char remains in a range of a lignite, with a caloric value from 20 to 24 MJ/KG. The byproduct of the process can be used as a soil conditioner.

Rest fraction

The remaining fraction, that is too small to be sorted, is processed by physicochemical and catalytic conversion. After feeding the residual fraction to the reactor, the water is completely evaporated and inorganic particles are converted back to their clean, dry and inert constituents. The steam and heat are used to generate electricity which provides power to the facility.